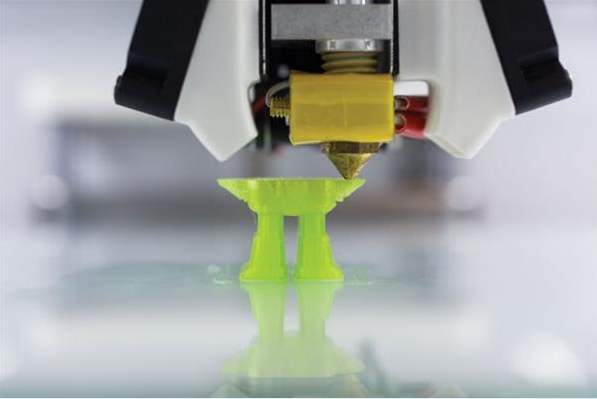

The benefits of plastic 3D printers

Today, we will explore plastic 3D printing and understand the main advantages of using this material for 3D printing. Plastic is still the most used material in the 3D printing industry. Why is this material so popular among users? How to use plastic correctly on 3D printers?

1. Able to 3D print large-size parts

If you need to make larger parts for the test project, plastic will be the best solution. Large-scale 3D printing is now becoming one of many companies interested in obtaining precise and customized parts. However, mass production using 3D printing can be very expensive. Because plastic is our most commonly used and cheapest material, you can more easily print multiple plastic 3D printed parts and assemble them.

2, the cost of plastic 3D printing is very low

Price is obviously one of the biggest advantages of plastic 3D printed parts. Using ABS or PLA materials, you can already print out parts at reasonable prices. If you focus on model accuracy or material strength, you can also use nylon material for high-precision printing.

3, use plastic 3D printing materials for small batch production

If 3D printing is regarded as a new method of prototyping, 3D printing has now become the main advantage of production because of the quality of new printing materials, the ability to create complex designs and customized products. Once again, you can use plastic materials for finished products. In addition, the numerous modifications that can be made to plastic parts can produce truly beautiful objects.

4, plastic 3D printing materials can provide a variety of surface treatment possibilities

When using plastic materials for 3D printing models, we often see subtle layers on the surface. For users in some special industries, it is necessary to perform the necessary post-processing work for 3D printing. The usual methods are polishing, coloring and polishing to make the plastic 3D printed model smooth and beautiful, which is crucial.

4. Higher efficiency than traditional injection molding

Plastic is one of the earliest materials used in the 3D printing industry, and 3D printed plastic is considered a cost-effective alternative to injection molding. Compared with technologies such as plastic injection molding, using 3D printing technology to make plastic parts is very simple. You do not need to customize production molds for prototyping or pre-production production. Just upload the 3D printing model file to the 3D printer. For each product iteration, you only need to use 3D printing software to process the model files, and then click "Print"!

5, plastic 3D printing materials are suitable for many fields

Plastic 3D printing can be used in the medical industry to create 3D printed models of organs. It can be used to replace automotive interior parts in the automotive industry, print architectural models, and even be used in the aerospace industry. In addition, from proof of concept, prototyping to production, plastic 3D printing materials are very useful for every step of the product development process! You can print any plastic components, plastic packaging or plastic products. You can use plastic-free 3D printing for any complex design.

6. Use plastic 3D printing to make prototypes

Plastic 3D printing material is the perfect solution for the prototyping process! If you are familiar with 3D printing technology, you will know that the 3D printing process is very promising in terms of prototyping. In fact, this is an ideal method for rapid prototyping, because you can use 3D modeling software to easily perform multiple product iterations at a low price.